Low Volume Production Services

Efficient, Cost-Effective

Manufacturing for Small Batches

At 3DFly, we provide low volume production solutions that are perfect for businesses, startups, and innovators looking to produce custom parts, pilot runs, or limited-edition products. With our advanced 3D printing, CNC machining, and post-processing capabilities, we deliver high-quality results without the costs and delays of traditional manufacturing.

Why Choose Low Volume Production?

Faster Time-to-Market – Launch and test your product in record time.

Cost Savings – No need for expensive molds or bulk orders.

Design Flexibility – Modify and refine between batches.

- Consistent Quality – High precision and repeatable results for every order.

B2B Collaboration for Low Volume Production

We work closely with manufacturers, product design firms, engineering companies, and startups to provide reliable small-batch manufacturing services across India. Our B2B collaboration model ensures:

- Seamless Integration into your supply chain.

- Confidential & Secure handling of all designs with NDA protection.

- Custom Production Schedules to align with your business timelines.

- Scalable Solutions that grow as your production needs increase.

Whether you’re outsourcing parts for prototyping, market testing, or short-run manufacturing, 3DFly becomes your trusted production partner.

Industries We Serve

Automotive Components

Medical Devices & Prosthetics

Consumer Products

Industrial Equipment

Electronics & IoT Devices

Architectural Models

Our Capabilities

Faster Time-to-Market – Launch and test your product in record time.

Cost Savings – No need for expensive molds or bulk orders.

Design Flexibility – Modify and refine between batches.

- Consistent Quality – High precision and repeatable results for every order.

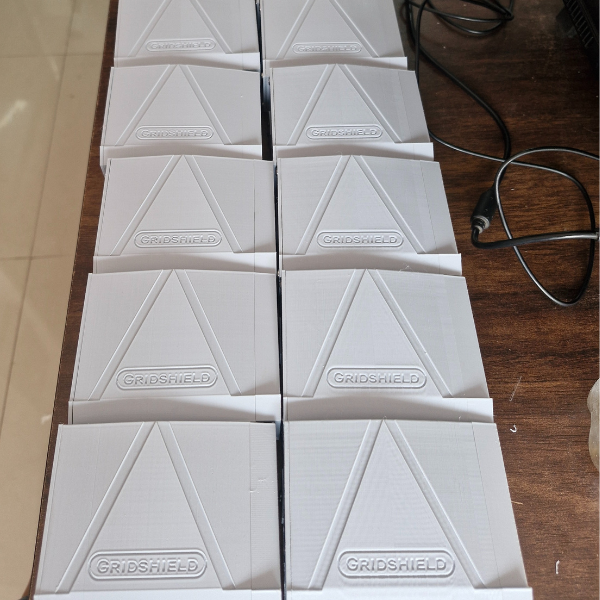

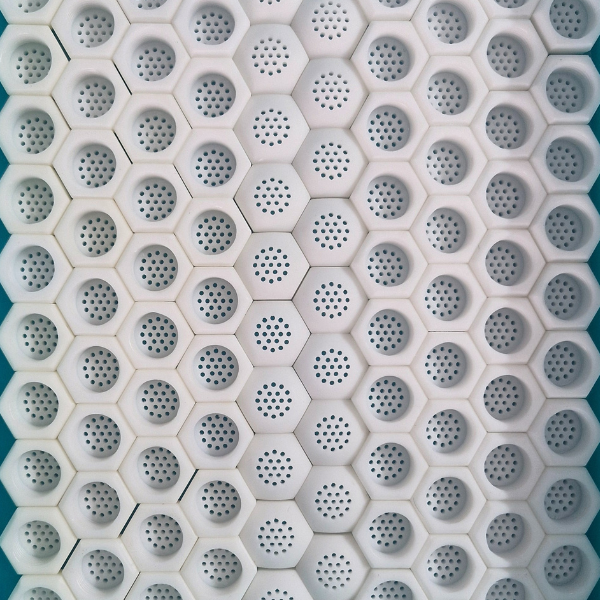

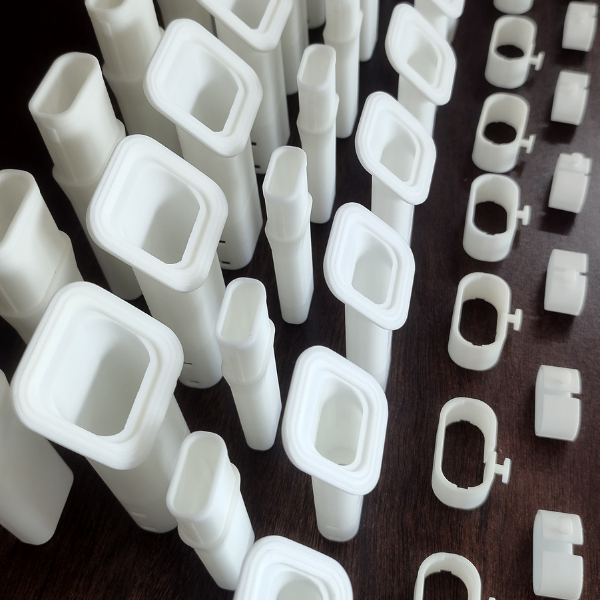

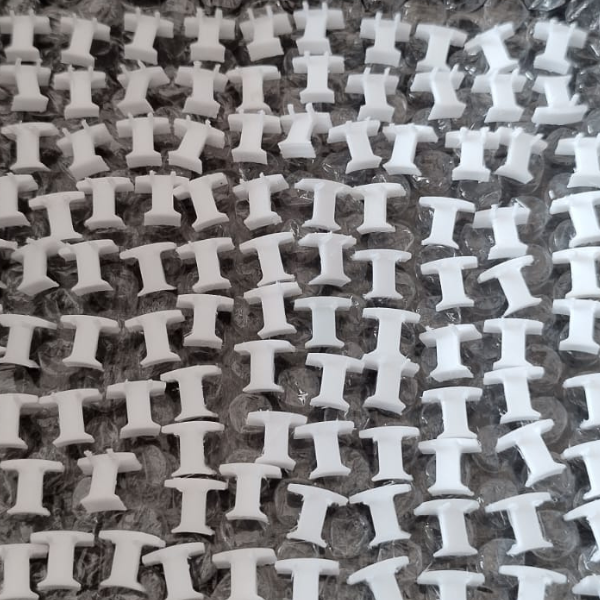

Some of Our Work Samples

Partner with 3DFly for your next low volume production run.

Discover Endless 3D Printing Possibilities,

Share your requirements -we’ll call you to bring your ideas to life